A whole host of factors influence the behaviour of dental implants in the mouth, such as the materials used in their components, the diameter or length of the implant, or the way it is anchored to the bone. An engineer in the UPV/EHU's department of Mechanical Engineering has made a study of these factors by means of numerical simulation, and has proposed ways of optimising them. The aim of the study is to prevent dental implants from failing and so that they behave correctly in the patients' mouths.

-

Ferreirak eta Bengoetxeak beren programak aurkeztu dituzte UPV/EHUko Klaustroan

-

UPV/EHUko 19 diziplina, munduko 500 onenen artean, Shanghaiko rankingaren arabera

-

Zientzia, Ingeniaritza eta Arkitekturako monografiarik onena

-

Medikuntza birsortzailearen etorkizunari buruzko gakoak

-

Beste pertsona bat al gara beste hizkuntza bat hitz egitean?

Computer simulations to improve dental implantology

A researcher at the UPV/EHU-University of the Basque Country is proposing improvements in dental implants by studying the forces, deformations and stresses they endure and generate

- Research

First publication date: 12/02/2016

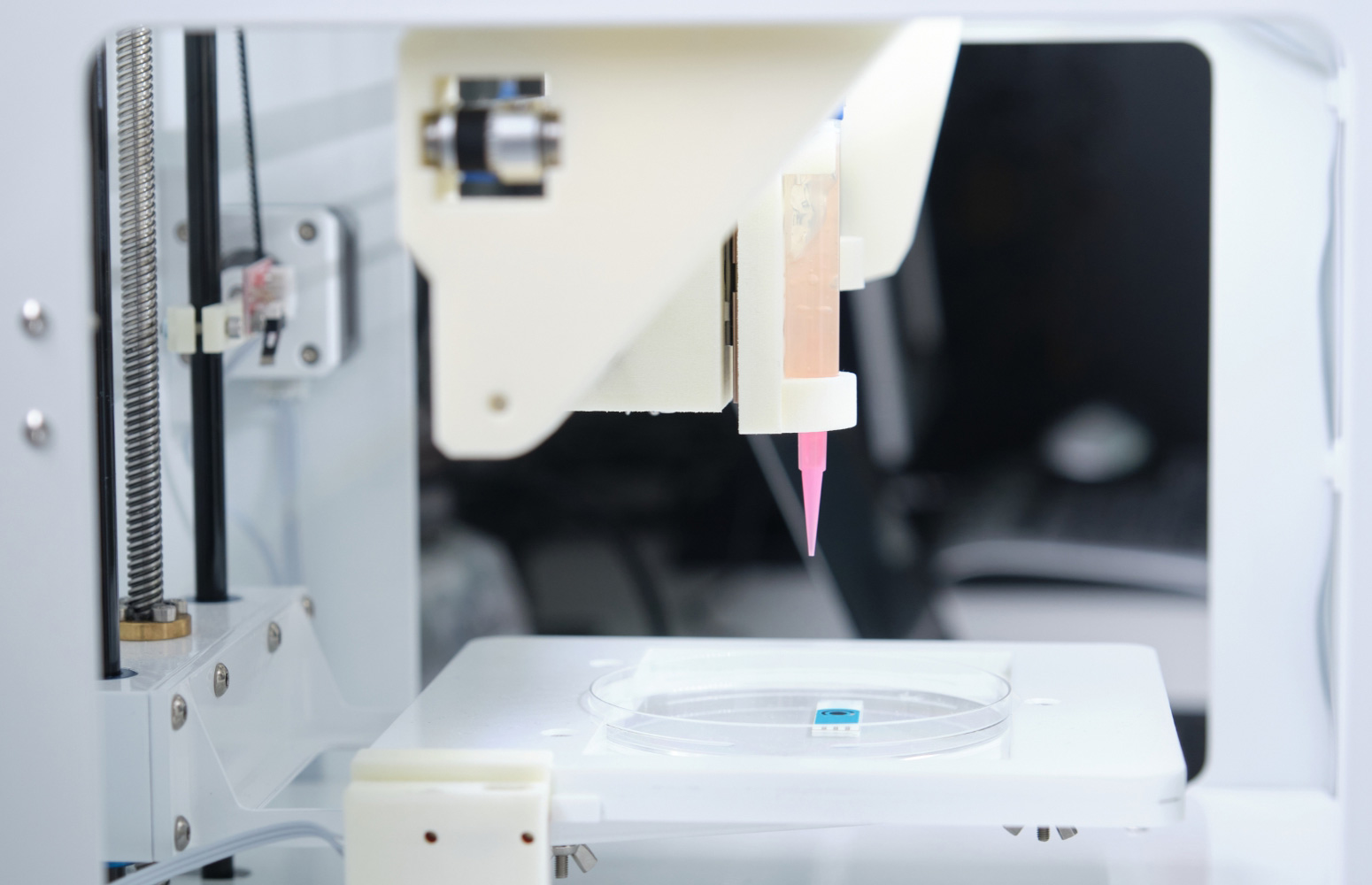

In his PhD thesis, the engineer Ugutz Garitaonaindia of the UPV/EHU's department of Mechanical Engineering, in collaboration with the company Createch Medical of Mendaro and the department of oral and maxillofacial surgery at University Hospital Donostia, has produced a detailed assessment of the mechanical behaviour of all the components of dental implants. Through computer programs it has been possible to model dental implants, the structures on the implants and the microimplants, and also simulate their behaviour.

"Numerous companies across the world produce dental implants and they are all looking for products offering the highest possible level of efficiency; in other words, the contact they have with the bone has to cause as little deformation and stress as possible, the components and structures of the implants need to transmit forces in the best way possible to the dental implant, etc.," explained Garitaonaindia. The screw of the dental implant, its size, diameter and shape, the materials that make up the rest of the parts, or the shape and way the microimplants used to anchor the different parts are fixed affect everything in a decisive way.

In his PhD thesis, Garitaonaindia is proposing a new way of studying the structures on the implants in a way that is more real. The fact of having available a method to carry out simulations of this type "could be of great help for the companies that manufacture implants as they allow their design to be improved, and also for doctors and health centres that fit microimplants and plates by means of surgery, as they can achieve better results," explained the researcher.

Garitaonaindia has expressed his intention of continuing with the lines of research started because "there are aspects to be improved and research to conduct; we will be going further into the subject and we are hoping to achieve some scientific publications". For example, the doctors he has been collaborating with have explained to him the weakness and areas for improvement that they have found in his work.

Additional information

Ugutz Garitaonaindia-Antsoategi (Arrasate-Mondragon, 1970) has degrees in Industrial Engineering (specialising in Mechanics) and Industrial Organisation Engineering, and is an assistant lecturer at the UPV/EHU's Faculty of Engineering in Gipuzkoa. His thesis is entitled "Análisis y optimización del comportamiento mecánico de implantes dentales mediante simulación numérica" (Analysis and optimization of the mechanical behaviour of dental implants using numerical simulation) and he wrote it up under the supervision of José Luiz Alcaraz-Tafalla, tenured lecturer at the UPV/EHU's Faculty of Engineering in Bilbao.

When conducting his research he had the collaboration of two organisations. In conjunction with the company Createch Medical SL of Mendaro he produced the study of the mechanical behaviour of the structures on the implants and the simulation work of the rigidity they transmit. And in the research into the microimplants that are normally used in oral and maxillofacial surgery he based himself on the microimplants of University Hospital Donostia.

Photos: UPV/EHU