Chitin is one of the most abundant renewable materials in nature and has great potential for manufacturing biodegradable products. The UPV/EHU’s BIOMAT group is working to obtain chitin using alternative sources such as squid pens, and to then validate it as a reinforcing agent in the manufacture of protein-based materials for biomedical applications.

Squid pens used to make scaffolds for biomedical applications

By upgrading food waste the UPV/EHU has developed a new biomaterial based on protein and chitin to manufacture scaffolds by means of 3D printing

- Research

First publication date: 30/05/2018

Using chitin-rich by-products of the food industry and following specific processing based on the principles of green chemistry, it is possible to obtain biomaterials that can be processed using techniques currently employed in industry. Chitin is the second most abundant natural polymer after cellulose and forms the exoskeleton of insects, arachnids and crustaceans, among others.

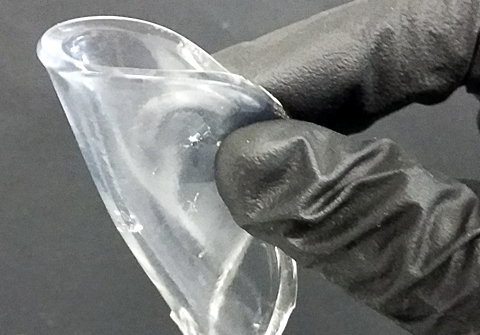

The UPV/EHU's BIOMAT group is working to obtain chitin from alternative sources. The raw materials used by the group are waste products from the canning industry and they hope to develop an optimised process to obtain chitin and protein from them; these materials could be used in a wide range of applications since they have properties of great interest, the most salient ones being their biocompatibility and biodegradability. In addition, it is possible to obtain materials in a whole range of formats (powder, pellets, film, hydrogel).

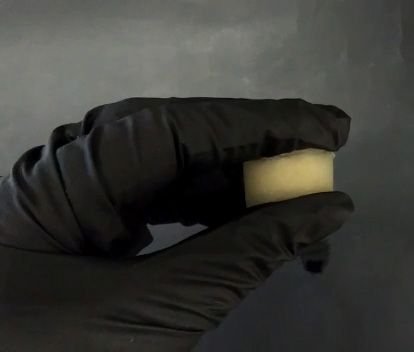

Chitin can also be used as a reinforcement in producing hydrogels for protein-based biomedical applications. Hydrogels are porous materials with a high water content and comprise molecular networks that provide them with great tensile strength and toughness; they meet a series of specific requirements with respect to biocompatibility, biodegradability and cytotoxicity needed for biomedical applications. The research group has in fact achieved very good results when using chitin produced from squid pens as a reinforcement in the manufacture of protein hydrogels.

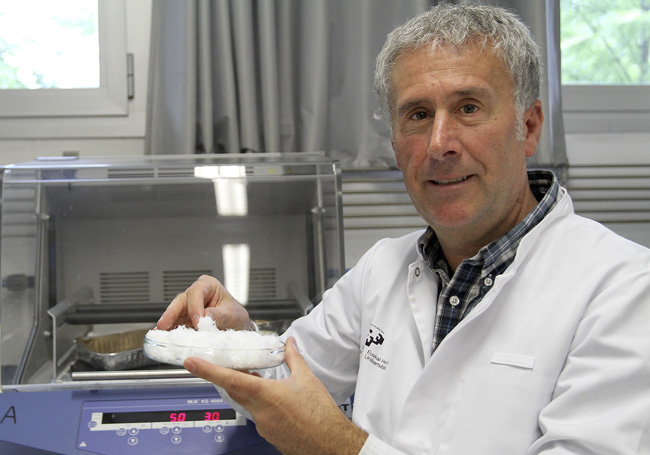

“Imagine a product made of protein, which is very light, very tough and which cells can stick to and grow. It sounds complicated, but in recent years we have been exploring how to denature proteins to be able to modify them depending on the properties needed for each specific application and, once denatured, they remain biocompatible and do not cause rejection,” stressed Pedro Guerrero, a BIOMAT group researcher.

Scaffolds for tissue engineering

“One of our aims involves developing new materials to formulate hydrogels similar to biological tissue, so these hydrogels need to display some specific properties to be able to interact with cells or drugs, for example,” explained the researcher.

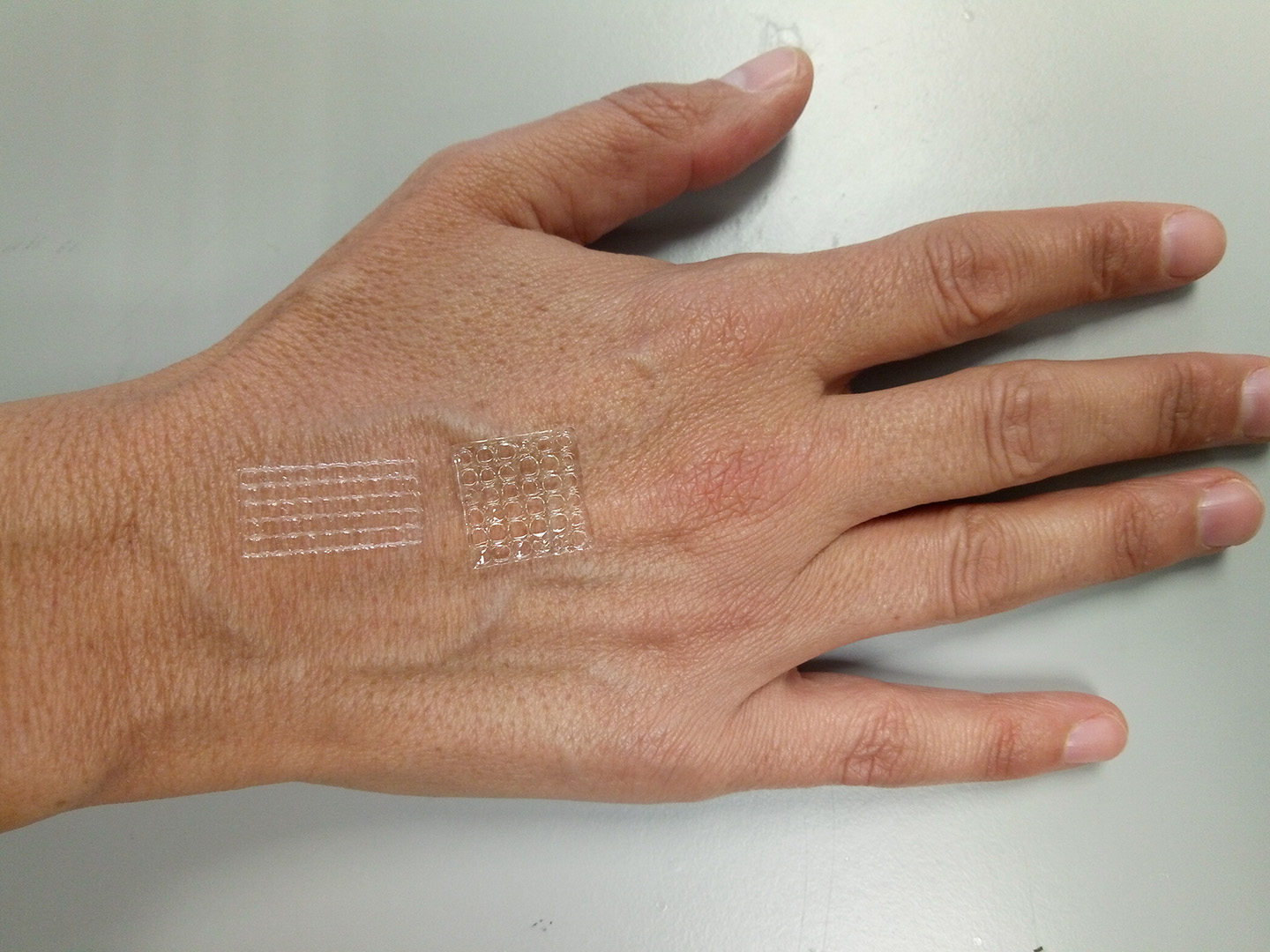

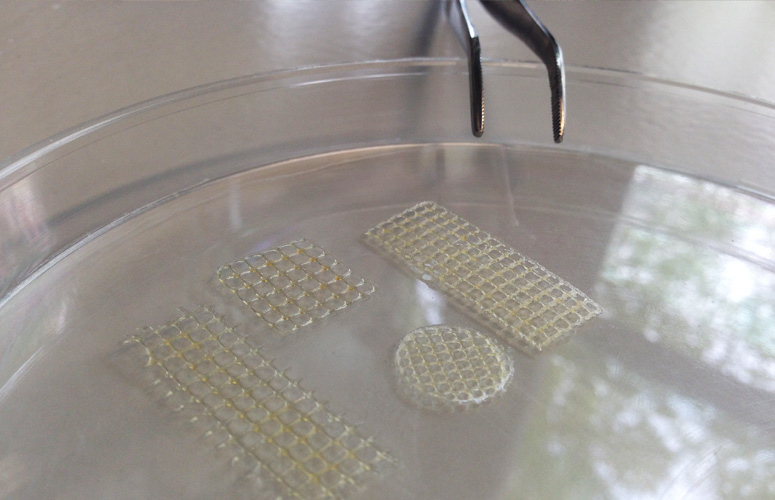

The BIOMAT group is aiming to develop a new material based on protein and chitin to manufacture innovative scaffolds and also to render this material suitable for additive manufacturing using Fused Deposition Modelling (FDM) technology, injection bioprinting and extrusion bioprinting. “New materials need to be developed to make 3D structures by examining not only the characteristics of the material but also its viability so that industrial techniques involving computer aided design can be used. The challenge does not lie solely in the technology of the printers, but also in the materials that are used to feed these printers,” added Dr Guerrero.

This strategy involves modulating and controlling the chemical, physical and biological properties under modulated reaction conditions to produce scaffolds for tissue engineering by depositing one layer of thermoplastic protein onto another successively until the scaffold has been built. One advantage from the outset is that protein-based materials are biocompatible and biodegradable and therefore suitable for tissue engineering.

Once the protein-based materials have been obtained, they have to meet a set of requirements if they are to be used in tissue engineering: be tissue biocompatible; display controlled biodegradability so that they can be replaced by tissue once it has regenerated; not be cytotoxic so as to prevent adverse responses in the body; display the mechanical properties required for each type of application depending on the location of the scaffold; and display appropriate porosity and morphology to encourage cell growth and the transporting of metabolites, nutrients and bioactive molecules both within the scaffold and between it and the surrounding environment. The results of the analyses, conducted in collaboration with the group of Dr Rosa Hernández at the UPV/EHU’s Faculty of Pharmacy, confirm the viability of the materials developed for biomedical applications.

Additional information

The BIOMAT group is a multidisciplinary research group made up of lecturers and researchers in the UPV/EHU’s departments of Chemical and Environmental Engineering, Applied Physics, Business Organisation and Applied Mathematics and who are working in the area of renewable, biodegradable materials for a range of applications. The research by the group focusses on the upgrading of industrial by-products and waste for the manufacture of biodegradable films and biocomposites, the modification of biopolymers, the optimising of bioplastic manufacturing processes and the environmental study of the products manufactured.

Bibliographic reference

- Versatile soy protein films and hydrogels by the incorporation of -chitin from squid pens (Loligo sp.)

- Green Chem., 2017,19, 5923-5931

- DOI: DOI: 10.1039/C7GC02982A